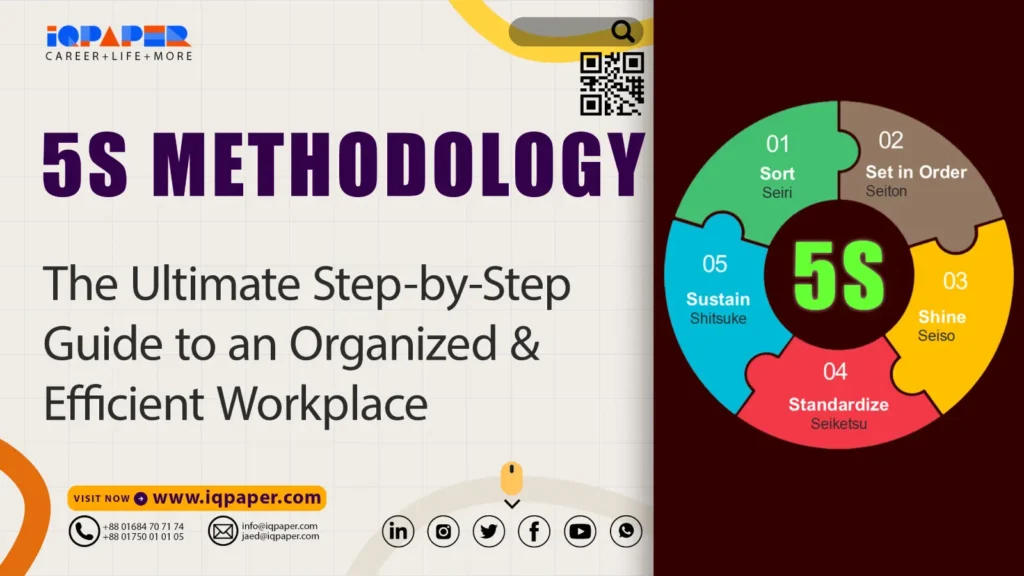

The 5S Methodology–

Each “S” represents a key step in the process:

1. Sort (Seiri)

Eliminate unnecessary items from the workplace. “When in doubt, throw it out!”

Ask yourself:

- Is this item essential for the job?

- Do we really need these items?

Examples:

- Excess or defective items

- Outdated or broken tools, jigs, and dies

- Worn-out parts, inserts, and inspection equipment

- Obsolete signs, memos, or posters

- Broken electrical equipment

Red Tag Method: A visual approach to identifying and removing unnecessary items:

- Attach red tags to unneeded or misplaced items.

- Document each tagged item.

- Maintain a “5S Tag Log” for reference.

- Discard obvious trash immediately.

2. Set in Order (Seiton)

Organize necessary items for easy access and return. Everything should have a designated place.

Ask yourself: Would a newcomer immediately know where each item belongs?

Benefits:

- Items are found quickly and easily.

- Time spent searching is minimized.

- Mistakes in retrieving the wrong parts are reduced.

- Walkways and workspaces remain clutter-free.

Implementation:

- Store frequently used items together in sequence.

- Create dedicated storage for tools.

- Keep infrequently used items away from the immediate workspace.

Think of a NASCAR pit crew: Every tool is positioned for maximum efficiency, eliminating wasted motion and errors.

3. Shine (Seiso)

Maintain cleanliness to ensure a safe and efficient workspace.

Ask yourself: Are there areas that need cleaning?

Benefits:

- Easier detection of defects and safety hazards.

- A tidy work area reduces tripping risks.

- Well-maintained machines function efficiently and last longer.

- A clean environment boosts team morale and pride.

Implementation:

- Identify cleaning targets.

- Set a cleaning schedule and assign responsibilities.

- Establish procedures for regular maintenance and inspection.

A clean work area is like a freshly washed car—imperfections become more visible, allowing for proactive maintenance.

4. Standardize (Seiketsu)

Create a structured, consistent approach to maintaining Sort, Set in Order, and Shine.

Ask yourself:

- Are the first three Ss consistently followed?

- Is 5S embedded in daily routines?

Benefits:

- Faster and easier training for new employees.

- Reduced errors and material waste.

- A safer, more organized workspace.

Implementation:

- Integrate 5S into daily operations.

- Establish clear documentation for procedures.

- Ensure visual cues indicate when items are out of place.

Consistency is key—when processes are clearly outlined and signed off, they are more likely to be followed.

5. Sustain (Shitsuke)

Make 5S a long-term habit rather than a temporary initiative.

Ask yourself: Are we slipping back into old, disorganized habits?

Benefits:

- A continuously clean and safe environment.

- Standardized, efficient workflows.

- Easier access to tools and materials.

- Higher employee morale.

Implementation:

- Keep 5S principles top of mind.

- Schedule daily maintenance tasks.

- Recognize and reward compliance.

- Conduct regular 5S audits.

Sustaining 5S requires commitment—practicing it daily ensures lasting benefits.

5S Summary

5S is a structured approach to maintaining an organized, efficient, and high-performing workplace. It allows employees to easily identify normal vs. abnormal conditions, supports continuous improvement, and enhances safety and productivity.

Key benefits of 5S include:

- A cleaner, safer workspace

- Increased efficiency

- Higher employee morale

- Standardized processes

By following all five steps—without skipping any—5S becomes a shared responsibility and a fundamental part of workplace culture.